| |

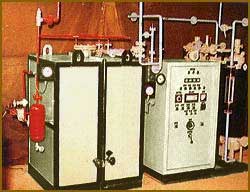

Ammonia Cracking

Units

MGS

Ammonia Cracking Units or Ammonia Cracker Gas Generator

produces mixture of Hydrogen and Nitrogen by cracking Ammonia,

which takes place in presence of Nickel catalyst at 850°C

temperature. MGS

Ammonia Cracking Units or Ammonia Cracker Gas Generator

produces mixture of Hydrogen and Nitrogen by cracking Ammonia,

which takes place in presence of Nickel catalyst at 850°C

temperature.

Ammonia Cracking Units / Ammonia Crackers

MGS Ammonia Cracking Units or Ammonia Crackers are fully

automatic, easily operational and are virtually maintenance

free . In addition they have a compact body and can be

installed very close to PSA Nitrogen generation equipment. The

cost of Hydrogen generation by this method comes to around

Rs.4.00 per Cubic Meter only.

Ammonia Crackers are very simple units. They are widely used

in industries for small generation of Hydrogen gas. Ammonia

Cracking Units are electrically heated units which consume

around 1.4KW power per Cubic Meter of Hydrogen. Raw material

for these units is Ammonia gas which is easily available in

standard 60kgs capacity cylinders in open market. When Ammonia

gas is passed over Nickel catalyst in these units, it cracks

into N2 + H2 mixture containing 75% Hydrogen and 25% Nitrogen.

This mixture is used as Deoxo Purification Unit for Oxygen

removal.

FOR GETTING PURE HYDROGEN

If pure Hydrogen gas of 99.99% purity is required, a PSA

Molecular sieves unit after these Ammonia crackers is provided

,which removes Nitrogen. This PSA unit operates at 7kg/cm²g

pressure and produces pure Hydrogen gas at 5.5kg/cm² pressure.

This type of ammonia based hydrogen generator is very

economical up to 50 Nm³/hr Hydrogen capacity.

MOLECULAR SIEVES PURIFIER

A Molecular sieve purifier is provided after Ammonia cracking

unit for reducing residual ammonia content and to get very dry

gas. This reduces ammonia down to 1-ppm level and dries gas up

to (-) 80°C dew point.

|

GAS COMPOSITION |

| |

Without Molecular Sieves

Purifier |

With Molecular Sieves

Purifier |

| Hydrogen |

75% |

75% |

| Nitrogen |

25% |

25% |

| Oxygen |

Nil |

Nil |

| Residual ammonia |

100-ppm(max) |

1-ppm (max) |

| Dew Point |

(-) 30°C |

Up to (-)80°C |

CAPACITIES

1 Nm³/hr to 600 Nm³/hr.

FEATURES

- Fully automatic, skid mounted units.

- Catalyst retort is made of heat resistant alloy which

can withstand max. 1150°C operating temperature.

- Furnace has efficient ceramic fiber insulation and a

hinged door for easy maintenance and easy inspection.

|

|