| |

Nitrogen Gas Generator .

Salient Features

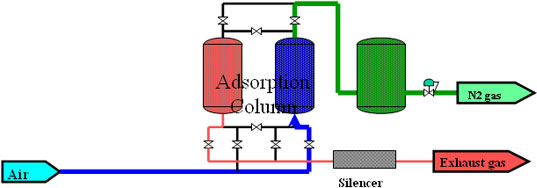

Working Principle

Pressure swing adsorption processes rely on the fact that

under

pressure, gases tend to be attracted to solid surfaces, or

"adsorbed". The higher the

pressure, the more gas is adsorbed; when the pressure is

reduced, the gas is released, or

desorbed. PSA processes can be used to separate gases in a

mixture because different

gases tend to be attracted to different solid surfaces more or

less strongly. If a gas mixture

such as air, for example, is passed under pressure through a

vessel containing an

adsorbent bed that attracts Oxygen more strongly than it does

Nitrogen, part or all of the

Oxygen will stay in the bed, and the gas coming out of the

vessel will be Nitrogen. When

the bed reaches the end of its capacity to adsorb Oxygen, it

can be regenerated by reducing

the pressure, thereby releasing the adsorbed Oxygen. It is

then ready for another cycle of

producing Nitrogen.

Specifications

MGS10HP Flow Rate

-- 10 LPM

Purity

-- 99.999%

Outlet Pressure

-- 4 - 6 Bar

Outlet Port

-- 1/8 inch

Noise Level

-- < 50 dBA

Feed Air inlet Flow

-- 60-80 LPM

Feed Air Inlet Pressure -- 120 – 140 Psig

Power

-- 230 +/- 10% ,1 Ph, 50HZ

Control

-- Automatic

Display

-- All Critical parameters

Installation

-- Indoor/outdoor with shelter

Operation Temp

-- 5 - 55 deg C

Size (in)

-- 20 x 20 x 45

Weight

-- 50 kg for Generator

Model No & Specification may change for betterment without

prior intimation and any optional item or features on request.

|

|