| |

PSA Nitrogen Gas

Generator We do Design & Engineering, Manufacturing and Installation

of Nitrogen generation systems for all applications, no matter

how large or small.

Nitrogen generators allow the user to produce their own

nitrogen using atmospheric air as raw material with well

proven PSA technology.

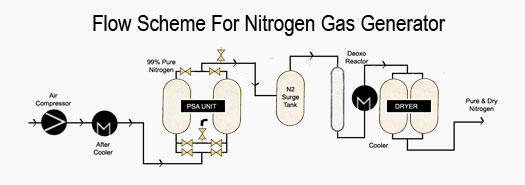

PRINCIPLE OF NITROGEN GAS GENERATION

Nitrogen gas from atmospheric air is separated by using Carbon

Molecular Sieves Technique . Carbon Molecular Sieves are used

in these generators to preferentially remove oxygen and other

minor gases from air .

The Nitrogen Gas Generators consist of a twin tower system

filled with Carbon Molecular Sieves. The process of "PRESSURE

SWING ADSORPTION" (PSA) is employed for smooth generation of

nitrogen. The compressed air is passed through one adsorber,

and Nitrogen comes out as product gas from it. The other

adsorber is simultaneously regenerated by de-pressurization to

atmospheric pressure.

MGS Nitrogen Pressure Swing Adsorption (NPSA)

Systems offer low-cost & in house nitrogen generation

facility.

MGS offers a wide range of nitrogen PSA Systems as per

client's requirement. The process parameters can be optimized

to meet specific flow, purity and pressure.

| Capacity: |

From 1 Nm3/hr to 1000 Nm3/hr |

| Pressure BAR: |

0.1-150 |

| Purity: |

From 95% to 99.99% |

| |

Ultra pure Nitrogen with purification unit

also offered |

| |

(Nitrogen purity up to

99.9999% can be

achieved |

| Moisture

content (Dew-Point): |

Minus 50 Deg. C Normal

up

to minus 70 Deg. C can be achieved |

| Gas analysis

Systems: |

|

| |

A) |

Oxygen Impurity |

On-line / portable oxygen analyzer |

| |

B) |

Moisture Content |

On-line / portable dew-point

analyzer |

| |

C) |

Flow |

Glass tube Rota meter /

flow recorder |

|

| Gas Storage: |

Offered as per customer's

requirement |

| Dimensions: |

Tailor made designs as per

customer's layout requirement |

NITROGEN PURITY

Nitrogen purity in the range of 99% to 99.9999% can be

produced through MGS Gas Generators. PSA ("MS" Model) Unit

produces raw Nitrogen of 99% to 99.99% purity. By adding

Purification Modules to this unit, Nitrogen of 99.9999% purity

may be produced. The Generator Models to produce Nitrogen with

higher levels of purity are as under:

TYPES OF NITROGEN GAS GENERATION SYSTEMS

| "MGS-MS" MODEL |

"MGS-DX'' MODEL |

"MGS-CU-DX" MODEL |

|

This model is most common

to produce Nitrogen of a purity in range from 95% to 99%

purity. By increasing the quantity of Carbon

Molecular Sieves, even 99.999% purity Nitrogen can be

produced from this model. Higher the purity, higher would be

the running cost. Considering operating cost factor, this model is recommended for purity upto

99.9% only. Plants with such purity specification are used for purging/inertizing

applications. |

Under this series of model

of nitrogen gas generators produce Nitrogen with oxygen

content of less that 1-ppm and variable percentage of

hydrogen which varies from 0.5 to 30% This hydrogen content

is desirable as reducing constituent in most of Heat

Treatment applications. This model is recommended for

use in Metallurgical industries to provide oxygen free

Nitrogen gas for Heat Treatment Furnaces. MS models can be

converted into this model by adding Halladium Deoxo reactor

and Dehydroation unit. This model also

finds applications in Chemical/Electronic Industries. |

The model

contains an extra Nitrogen Purification Module based on

Copper Deoxo Catalyst. This model finds application in

synthetic fiber, optical cables and electronic industries.

Cost of production of Nitrogen from this model is highest.

It produces very pure Nitrogen gas which is free from Oxygen

as well as Hydrogen. and finds its suitability for

applications where hydrogen contents are detrimental to the

process. |

Standard Gas Composition

| GAS COMPOSITION |

MGS-MS-L |

MGS-MS-H |

MGS-DX |

MGS-CU-DX |

| Oxygen |

0.5 to 4% |

10-ppm to 0.5% |

1 to 3ppm (max) |

1-ppm (max) |

| Hydrogen |

Nil |

Nil |

0.5% or more |

Nil |

| Nitrogen |

96-99.5% |

99.5 to 99.999% |

Balance |

99.9999% |

| Dew Point |

(-)40°C to (-) 80°C |

(-)60°C to (-) 80°C |

(-)40°C to (-)80°C |

(-)40°C to (-)80°C |

| Applications |

As Inert Gas in Chemical

Industries, Food & Pharmaceutical Industries, for fire

control in Coal Mines etc. |

As Inert Gas in Chemical

Food, Pharmaceutical Industries, Heat Treatment Furnaces,

Electronic, Synthetic, Fibre, Industries |

As Inert Gas in Chemical &

Pharmaceutical Industries In applications where oxygen

impurity is not tolerable. |

As Inert Gas in Electronic,

Synthetic Fiber, Hitech Industries where one needs Ultra

High Purity gases. |

Note:- However a system can

be designed to suit individual's specific requirements.

Salient Features

-

Automatic Start and stop. Start-up

time is only 5-Minutes.

-

Nitrogen gas supply is always

under control.

-

Self-contained Skid mounted units

for easy installation.

-

Very low maintenance costs.

-

Very simple to operate.

-

Carbon Molecular Sieves life is

minimum 8-10 Years.

-

Very low cost of production.

-

Compact in size and design.

-

Pay back periods are very short in

the range of 1-2 years depending upon applications.

NITROGEN PRESSURE

Standard PSA Nitrogen Gas Generators produce Nitrogen at a

pressure of 5.5 to 6.0Kg/cm²g. This pressure comes

automatically as feed air compressor supply feeds the

compressed air at 7Kg/cm²g pressure to the PSA Unit. By

increasing feed air pressure to 10Kg/cm²g, Nitrogen can be

produced at 8.5Kg/cm²g. pressure also. It is, however most

economical to run Air Compressor at around 7Kg/cm²g pressure

and produce Nitrogen at 5.5Kg/cm²g. pressure. If Nitrogen is

needed at high pressure, Nitrogen booster compressor is

provided after the gas generator. By this addition, it is

possible to compress Nitrogen gas to obtain desirable pressure

to suit individual's requirements. Standard PSA Nitrogen Gas Generators produce Nitrogen at a

pressure of 5.5 to 6.0Kg/cm²g. This pressure comes

automatically as feed air compressor supply feeds the

compressed air at 7Kg/cm²g pressure to the PSA Unit. By

increasing feed air pressure to 10Kg/cm²g, Nitrogen can be

produced at 8.5Kg/cm²g. pressure also. It is, however most

economical to run Air Compressor at around 7Kg/cm²g pressure

and produce Nitrogen at 5.5Kg/cm²g. pressure. If Nitrogen is

needed at high pressure, Nitrogen booster compressor is

provided after the gas generator. By this addition, it is

possible to compress Nitrogen gas to obtain desirable pressure

to suit individual's requirements.

NITROGEN STORAGE TANK

At

the outlet of PSA Nitrogen Generator, Nitrogen gas is

available at a pressure of around 5.5kg/cm2g. Storage Tank

receives Nitrogen from the Gas Generator and supplies it to

your process as per demand. Normally Nitrogen Storage System

of 1-hour capacity is considered to be adequate. For high

storage requirements, a Nitrogen Booster Compressor is

provided to store the gas at high pressures to keep storage

Tank size smaller. Nitrogen Storage Tanks are fabricated from

Boiler Quality Steel under 3rd party inspection. The Gas

Generator automatically trips when pressure reaches the set

value. When pressure in the tank falls, Gas Generator

re-starts. At

the outlet of PSA Nitrogen Generator, Nitrogen gas is

available at a pressure of around 5.5kg/cm2g. Storage Tank

receives Nitrogen from the Gas Generator and supplies it to

your process as per demand. Normally Nitrogen Storage System

of 1-hour capacity is considered to be adequate. For high

storage requirements, a Nitrogen Booster Compressor is

provided to store the gas at high pressures to keep storage

Tank size smaller. Nitrogen Storage Tanks are fabricated from

Boiler Quality Steel under 3rd party inspection. The Gas

Generator automatically trips when pressure reaches the set

value. When pressure in the tank falls, Gas Generator

re-starts.

HYDROGEN REQUIREMENT

For high purity Nitrogen Gas Generators, a Deoxo Unit is

provided where oxygen in nitrogen gas is removed by reacting

it with Hydrogen. This Hydrogen can be supplied either from

Hydrogen Cylinders or captive Hydrogen Generator based on

Ammonia Cracking Process. In smaller capacity Nitrogen Gas

Generators, Hydrogen requirement is very little, therefore

Hydrogen Cylinders are most economical. But, in bigger

capacity Nitrogen Gas Generators Ammonia Cracking unit works

out to be more economical.

NITROGEN CYLINDERS V/S NITROGEN GAS GENERATORS

NITROGEN CYLINDERS

Nitrogen Cylinder costs

Rs.10/- to Rs.15/-per Cubic Meter. which is very high in

campier to cost of Nitrogen produced from PSA based Nitrogen

gas generators. Transfer and handling of Gas

Cylinders is very cumbersome due to high pressure risks.

Dependency on availability

of Nitrogen Cylinders all the time. Nitrogen purity in Cylinders

is never reliable and changes from cylinder to cylinder.

There are many factors like

location, market demands transportation mishandling, left

over gas in the cylinders etc. which affect the availability

& economy of the main process.

NITROGEN GAS GENERATORS

Nitrogen Gas Generator gas

costs Rs.2/- per NM³ only. In-house Nitrogen generation

as and when needed. Continuous and reliable

Nitrogen supply round the clock. Production never suffers

due to shortage of Nitrogen Gas. Nitrogen Purity is very

steady and reliable. Plant handling is very easy.

|

|