| |

PSA Oxygen Gas

Generator

PSA

Oxygen Gas Generator / Plant manufactured by MGS offer

low-cost Oxygen with a highly reliable supply alternative. PSA

Oxygen Gas Generator / Plant manufactured by MGS offer

low-cost Oxygen with a highly reliable supply alternative.

We offer a wide range of Oxygen PSA Systems to suit individual

client's requirement. The process parameters are optimized to

meet specific flow, purity and pressure.

PSA Oxygen generation is based upon the adsorption technology

which is a physical separation process using different

adsorption affinities of gases to a micrporous solid substance

,called molecular sieves. Nitrogen has a higher adsorption

capacity to zeolite molecular sieves of special grade than

oxygen. This characteristic is used with the PSA plants for

generation of plants .

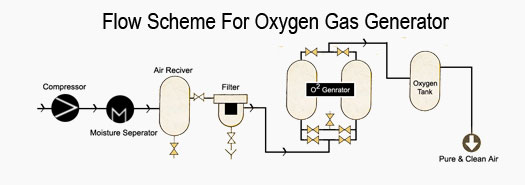

The method of generating oxygen from oxygen gas plant involves

taking air from an air compressor. It has 2 vessels feeded

with special grade of molecular sieves. Clean compressed air

at an ambient temperature is passed through one vessel and

oxygen comes out as product gas and other vessel is de

pressurized to atmospheric pressure and purge with little

quantity of oxygen coming out from first vessel. This

regenerates molecular sieves which is used in next cycle. Thus

second vessel keeps cycling alternately in oxygen production

and regeneration making oxygen gas available continuously to

PSA oxygen unit.

MGS Oxygen Pressure Swing Adsorption (OPSA) Systems offer

low-cost Oxygen with a high supply alternative.

MGS offers a wide range of oxygen PSA System as per client's

requirement. The process parameters can be optimized to meet

specific flow, purity and pressure.

| Capacity: |

From 1 Nm3/hr

to 200 Nm3/hr |

| Pressure

PSIG: |

20-50 |

| Purity: |

From 85% to 95% (As per

customer requirement) |

| Moisture

content (Dew-Point): |

Minus 40 Deg. C Normal

|

| Gas analysis

Systems: |

|

| |

A) |

Oxygen Impurity |

On-line oxygen analyzer |

| |

B) |

Moisture Content |

On-line dew-point

analyzer are offered |

| |

C) |

Flow |

Glass tube Rota meter |

|

| Gas Storage: |

Offer as per customers

requirement |

| Dimensions: |

Tailor made designs as per

customer's layout requirement |

| Power

consumption: |

1 in

smaller size & 0.8Kw/m3

in bigger size |

| Utilitys: |

cooling water

and electrical power |

Cost of Oxygen Generation:

Rs.2/- per cubic meter only compared to Rs.8/- per cubic

cylinder oxygen.

Advantages of Oxygen PSA Systems:

-

Proven PSA technology produces

highly reliable Oxygen supply at your site.

-

User friendly designs with few

moving parts means minimal maintenance, maximum reliability.

-

Economizer shuts system down

during low demand to increase savings.

-

Microprocessor-control system

allows unattended operation and maintains highest efficiency.

-

Tailor made designs as per

client’s layout requirement

-

Precision-engineered switch-over

valves provide high reliability with minimal maintenance.

Application of Oxygen

Glass Industry, Ampules & Vials Manufacturing, Brazing,

Hospital, Fish Farming , Refinery , Water Treatment, Sewage

Treatment, Chemical and Petrochemical Plants, Metal Treatment,

Electronic / laboratory Applications, Welding, Pulp & Paper

Salient Features

-

Cost effective - Since the unit

will pay for itself very fast, then the only cost will be

operational cost i.e.- electricity.

-

Compact Body - The unit requires

only 2.5 x 2.0M for size of 5NM³/hour oxygen generator.

-

Easy Installation & usage - Fully

automatic unit.

-

Tested Design - Virtually

maintenance free.

-

Round the Clock Supply - If

required, the unit can be operated continuously.

-

Safe and Convenient - No hazardous

oxygen cylinders.

-

Least Expensive Oxygen Source -For

welding, brazing, cutting, melting and glass making etc.

-

Several Models - To meet

individual customer's requirement.

Oxygen Gas Plant Models

| Model |

Capacity |

Power

Requirement |

Cooling

Water Requirements |

Space |

| |

Cu.

Meter/Hr |

KW |

M3/hr

|

L*W*H

(meters) |

| MGSOG-1 |

1 |

2.0 |

- |

1.5*1.5*2.0 |

| MGSOG-3 |

3 |

5.0 |

0.5 |

1.5*1.8*2.0 |

| MGSOG-5 |

5 |

8.0 |

0.8 |

1.5*1.8*2.0 |

| MGSOG-10 |

10 |

14.0 |

1.5 |

2.0*2.0*2.2 |

| MGSOG-15 |

15 |

20.0 |

2.0 |

3.0*2.0*2.2 |

| MGSOG-20 |

20 |

23.0 |

2.5 |

3.5*2.0*2.2 |

| MGSOG-25 |

15 |

30.0 |

2.5 |

4.0*2.5*2.2 |

| MGSOG-30 |

20 |

32.0 |

3.0 |

5.0*3.0*2.2 |

| MGSOG-45 |

45 |

50.0 |

5.0 |

6.0*3.5*2.5 |

| MGSOG-60 |

60 |

65.0 |

6.0 |

6.0*3.5*2.5 |

| MGSOG-75 |

75 |

90.0 |

8.0 |

7.0*4.0*2.5 |

| MGSOG-100 |

100 |

115.0 |

10.0 |

8.0*4.0*2.5 |

|

|